Robotic Morphologies at the IstanbulDesign Biennial

Robotic Morphologies is a creative response to a call for the robotic production of an exhibition piece and

its design process’ for 4th Istanbul Design Biennale under Docendo Discimus Instrumantae

(DDI) by FABB. DDI dwells on the concept of “instruction sets” and

“process for digital fabrication” that are centred on master/apprentice/tool interrelation. As part of DDI,

six teams from all over the world such as Australia, USA, Turkey, Denmark and France prepared instruction

sets using different processes for digital fabrication such as milling, hot-wire cutting, rod bending,

weaving. These instruction sets and processes of fabrication are all tested in workshops that took place in

each respective countries. The learnings from these workshops are then translated into the final instruction

sets and shared along with the tools and materials during the Biennale from 22 September – 4 November 2018.

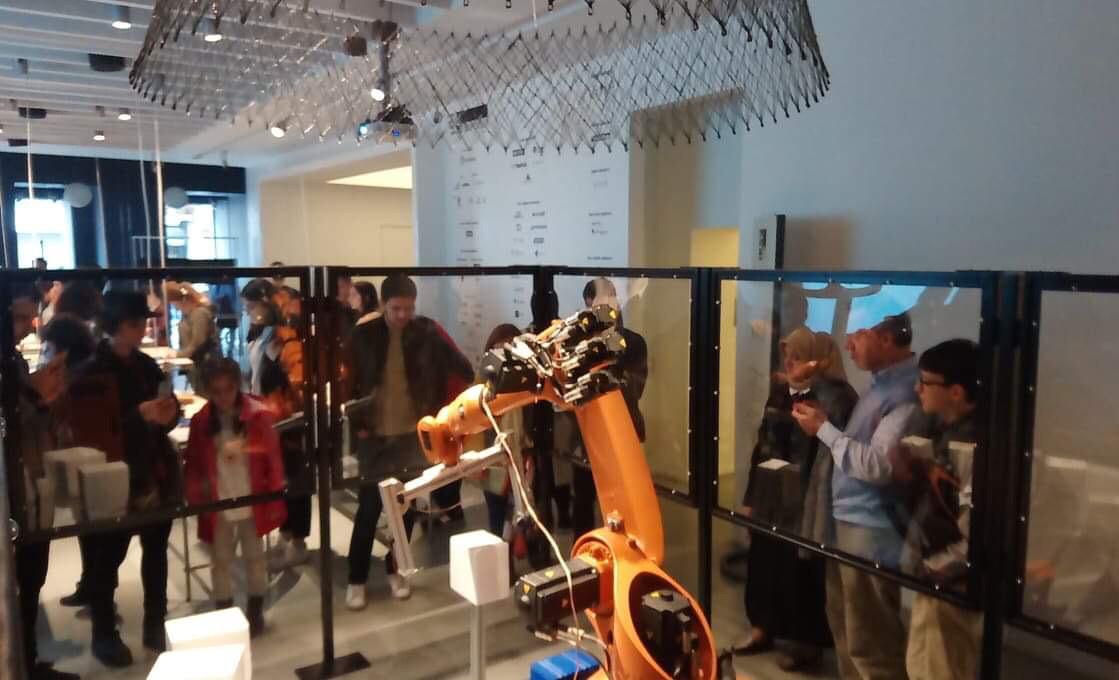

Each exhibition piece is then fabricated during the Biennale. Robotic Morphologies is manufactured during

the third week of the Biennale and designed through human-computer interaction.

Borrowing the concept of Thieri Foulc’s 2D-rule based Morpholo Game, the idea of Robotic Morphologies is to

design a new partition element through a continuous workflow of digital design to robotic production. Using

a computational interactive web

interface, the users adjust parameters and create patterns that inform a 3D modelling software to

design and produce a partition element. Each partition element consists of 10 x 15 cubes. Using an

industrial robotic arm such as UR10 and a custom made hotwire cutter as an end effector, a generic cube is

transformed to match the designs. Once the final form of the cube is ready, it is then added to the

exhibition piece.

As part of the DDI brief, a workshop was organised at QUT Design Robotics; including architecture,

industrial design and interaction design students from QUT School of Design and UQ School of Architecture.

This workshop allowed non-expert users to engage with highly complex programming tasks of industrial robotic

arms. In this workshop, the limitations of the workflow, as well as popularising the complex knowledge

required for controlling industrial robotic arms were tested.

As the artwork was designed through a collaborative and open framework, this allowed users to engage with

the design process in its early stages. This democratisation of the design process allowed users to identify

and influence the limitations and the possibilities of the interface. The results of this work suggest that

advanced manufacturing technologies can be made available to non-specialist users when each step of the

design is clearly identified and the user interactions at early stages enhance the involvement with these

technologies and the possible creative outcomes.